Our Buildings

PIONEER STEEL BUILDINGS ARE BUILT TO LAST

Limited Only by Your Imagination!

Pioneer Steel bases its designs of prefabricated metal buildings on a standard sized panel. These panels come with a width and length (approximately 2’ x 10’). The way you decide to put them together is your choice. Creating custom shapes and sizes is easy.

Superior engineering will help you achieve the results quickly, efficiently, and with a minimum of labor. Every Pioneer Steel building features a clear span design. Any expansion or customization will largely depend on your specific requirements and needs.

Some Other Design Ideas to Consider

OPEN SIDED

A single radius, partial arch structure, clear span with structural frame supports on open side. Standard sizes range from 19' wide to 50' wide with open side clearances of 8', 10', 12', 14', 16' and varying bay spacings.

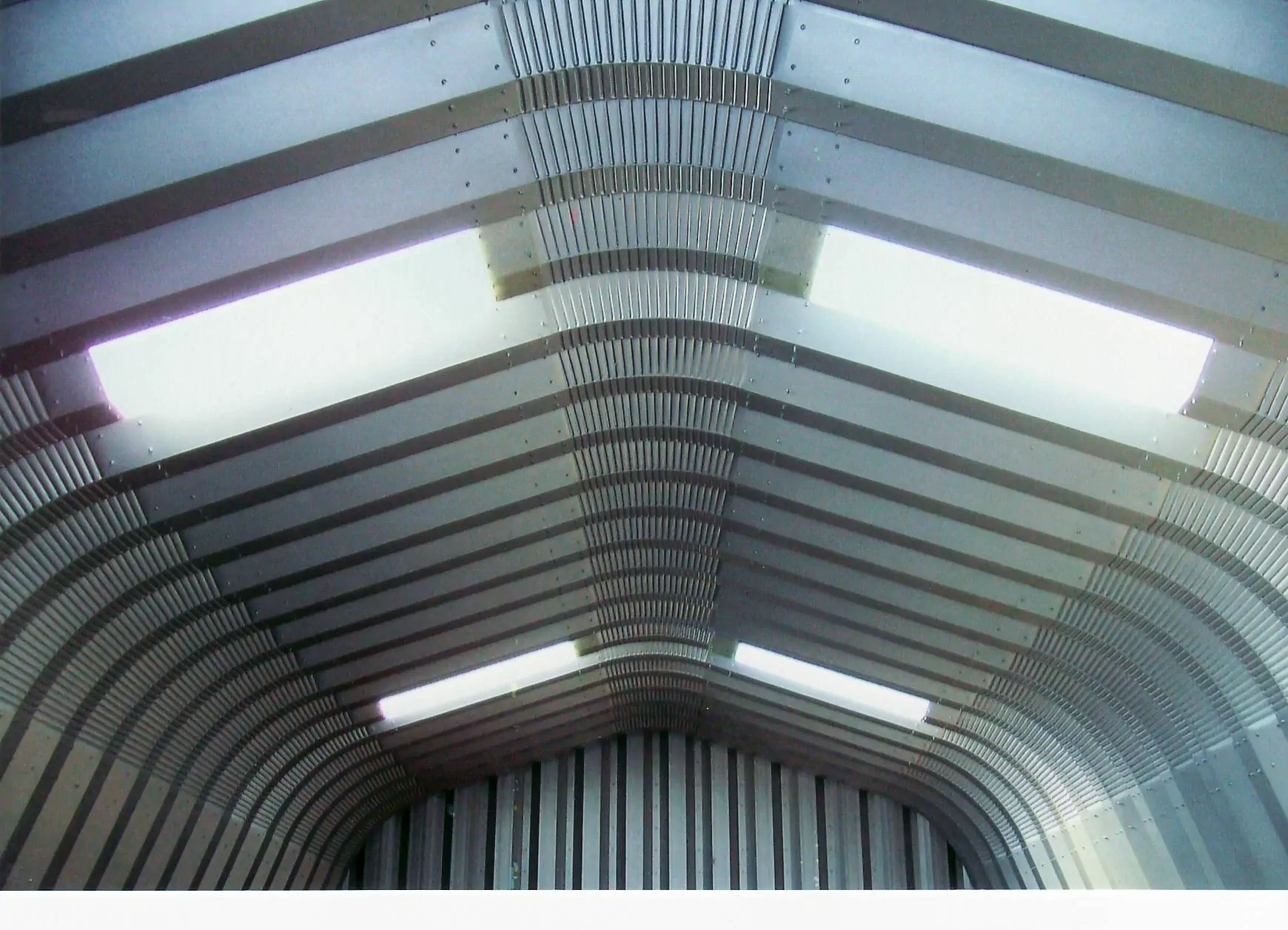

Roof Systems

A low-profile arch structure with a single radius clear span. Designed and created to function as a roof system, using traditional wall designs for sidewall support. Standard sizes range from 30' wide to 90' wide with heights in the 10' to 30' region.

Multiple Arch Spans

A series of single radius arch structures sharing a common structural support system as an interior wall. Standard sizes range from 30' to 70' wide for each individual span. You can connect these spans next to each other in numerous combinations. Multiple Arch Spans can range from double span to triple span and beyond.

Conveyor Covers

You can use either single radius or multiple radius clear span arch structures. These structures cover standard single or double conveyors and serve as a gallery. Standard sizes range from 10' wide to 30' wide. And come with heights and sidewall clearances to accommodate any combination of conveyor and walkway systems.

Accessories

Pioneer Steel buildings offer a diverse range of metal accessories suitable for all models. These include ventilators and skylights, providing ample air and light, along with an extensive array of doors for convenient access to your building. Pioneer Steel makes construction easy with pre-drilled base plates, self-adhesive caulking strips, and insulation pins that are simple to install. With Pioneer Steel buildings, you can expect long-lasting durability, cost-effectiveness, and unparalleled ease in building your structure.

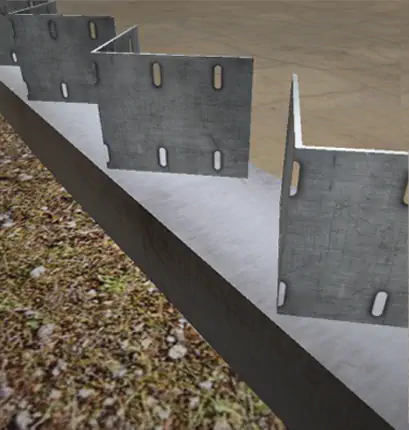

Baseplates

Pioneer Steel baseplates make building simple and economical with surprising DIY ease. These pre-drilled template-system plates are available in two options.

Either the standard “U Channel” or our special maintenance-free Industrial Quality model. Whichever baseplate option you decide on will depend on your foundation requirements. Each design integrates with current bases, avoiding the need for excavation. A real benefit when considering straightforward and future relocation.

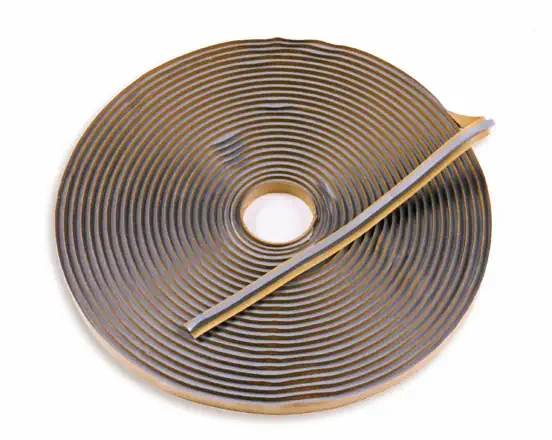

Caulking

This optional feature is the Pioneer self-adhesive, wax-backed Caulking Strip. Our Caulking Strips are made with high-quality Butyl Rubber. This material keeps its consistency in many different temperatures.

These easy-to-use strips offer long-lasting protection from the elements. They give you peace of mind you can trust.

Bolts

Assembly of our prefab metal buildings is easy. You assemble your Pioneer Steel structures using a single bolt size throughout.

Pioneer Steel bolts are durable. We use only exclusive Leland JS1000™ plated bolts that meet and exceed 1,000 hours of salt spray testing!

These bolts have an extremely powerful corrosion resistant coating that maximizes their life. Our bolts are more durable than anything commonly available on the market today and are self-healing after scratching. The JS1000 is totally compatible with Aluminum (no Galvanic reaction), as well as other metals used in construction.

All Pioneer Steel buildings come with the standard 1000-hour Corrosion Test Bolts. For areas needing better protection from corrosion, like coastal regions, we offer 1500-hour Corrosion Test Bolts. These bolts provide you additional protection and security. A great benefit, knowing that your metal building is even more storm-resistant and protected from the elements.

The JS1000 coating process is non-toxic. In fact, the JS1000 bolt has been FDA approved for use with food products. In addition, the coating is hexavalent chromium free and R.O.H.S compliant.

The United States and European countries require that all plating follow this important rule. This rule limits certain dangerous substances.

Service Doors

Pioneer Steel offers a wide variety of ready-made doors including Sectional Overhead and various walk-in doors. We also offer our in-house 4’x7’ Service Door. We build our doors to your particular specifications, or you can install a standard door frame and door.

Ventilators

We understand the need for proper ventilation. Proper ventilation not only helps control the temperature inside your metal building, but also the humidity and air pressure.

We designed our ventilators to fit easily in your prefab building. You can choose between the low-wind Turbo Vent or the fixed Gravity Vent models. The custom engineered fit guarantees a barrier from the elements and animals.

Skylights

You can choose any color you like for these long-lasting fiberglass skylights. They are heavy-duty and provide up to 20 sq ft of natural light per panel. This helps brighten the inside of your metal building during the day without using electricity. We manufacture our skylights in 12, 16, and 24 oz weights.

Overhead Doors

Another space saver for accessing your steel building, are our overhead doors which feature:

THE STRENGTH TO BLOCK NOISE AND WEATHER: Commercial insulated doors resist the elements and greatly reduce outside noise. All while enhancing the overall aesthetics of your building at the same time. Choosing one of our insulated doors will help increase energy savings. Our environmentally compliant polyurethane provides one of the highest R-Values available in sectional doors.

We construct our garage doors from steel that contains 80% recycled material. Roll-formed galvanized steel struts and double-end hinges reinforce them. This is to meet wind load specifications and to comply with ANSI/DASMA 102-2004. You can find the protective coating system on both the interior and exterior steel.

ENVIRONMENTALLY COMPLIANT POLYURETHANE CONSTRUCTION: The polyurethane foam in our garage door section is fully enclosed inside the steel skins. This design puts the insulation properties of polyurethane foam far ahead of polystyrene foam for performance and value.

Polyurethane foam is a two-part system. The process starts with two chemical mixtures that, when combined, expand and set to fill the garage door panel. During the expansion, the foam fills the inside of the panel. It adheres entirely to the metal surfaces of the garage door panel. This creates a strong and rigid composite structure.

When enclosed within a garage door section, polyurethane foams remain completely stable. Insulating with polyurethane provides a superior product with higher insulation properties and a stronger unitized section.

DURABLE HARDWARE: The track is constructed from 2" or 3" galvanized steel, depending on the dimensions of the door. It has a bracket mount for wood jambs or a continuous reverse mount for steel jambs. For angle-mount track, door widths are 2" wider than the opening.

Track rollers are 2" or 3" case-hardened inner and outer steel races with 10-ball pre-lubricated bearings. Hinges, brackets and reinforcing struts are hot-dipped galvanized steel. The fasteners are placed for maximum corrosion resistance.

Counterbalancing springs are torsion type, computer calibrated to match door load. This provides a 10,000-cycle life at the minimum; optional spring wires can achieve 25,000, 50,000 and 100,000 cycle requirements. Springs are wound from oil-tempered wire and mounted on a continuous cross header tube or solid shaft, as determined by torque load.

Insulation Pins

A necessity for anyone who wants to insulate their metal building themselves. These insulation pins are easy to attach and screw directly on to the building kit bolts. This helps attach fiberglass insulation to your metal building’s structure. Insulating your metal building makes it suitable for year-round use.